Quality Engine Services

Go to Block Re-Surfacing

Block Re-Surfacing

Surfacing is done via our Storm Vulcan RT17y Surface Grinder with CBN Carbine Disk with a True Deck fixture to precisely surface blocks cylinder heads.

Go to Cylinder and Rod Honing

Cylinder and Rod Honing

With a Sunnen Rod Honer, Quality Machine produces a round and straight honed bore, in all respects equal to or better than the manufacturers’ new rods.

Go to Engine Balancing

Engine Balancing

Quality Machine uses a HINES Universal Balancing Machine. This model of balancing machine can be used for both single and two plane rotor balancing.

Go to Dyno testing

Dyno testing

For Dyno testing any GM, Ford or Chrysler engine, Quality Machine utilizes a Super Flo SF-902s designed for high RPM and maximum durability.

Resurfacing

Honing

Balancing

Testing

Honing

Balancing

Testing

Experience

With over 30 years in the automotive industry, Southern Oregon’s Quality Machine Corporation is your choice for all your machine shop needs.

Quality

Quality Machine Corporation has state-of-the-art engine machine tools, including a full Dyno, that achieve the highest quality standards and results.

Services

Quality Machine Corporation offers a full line of engine machine services including cleaning and crack detection and engine balancing.

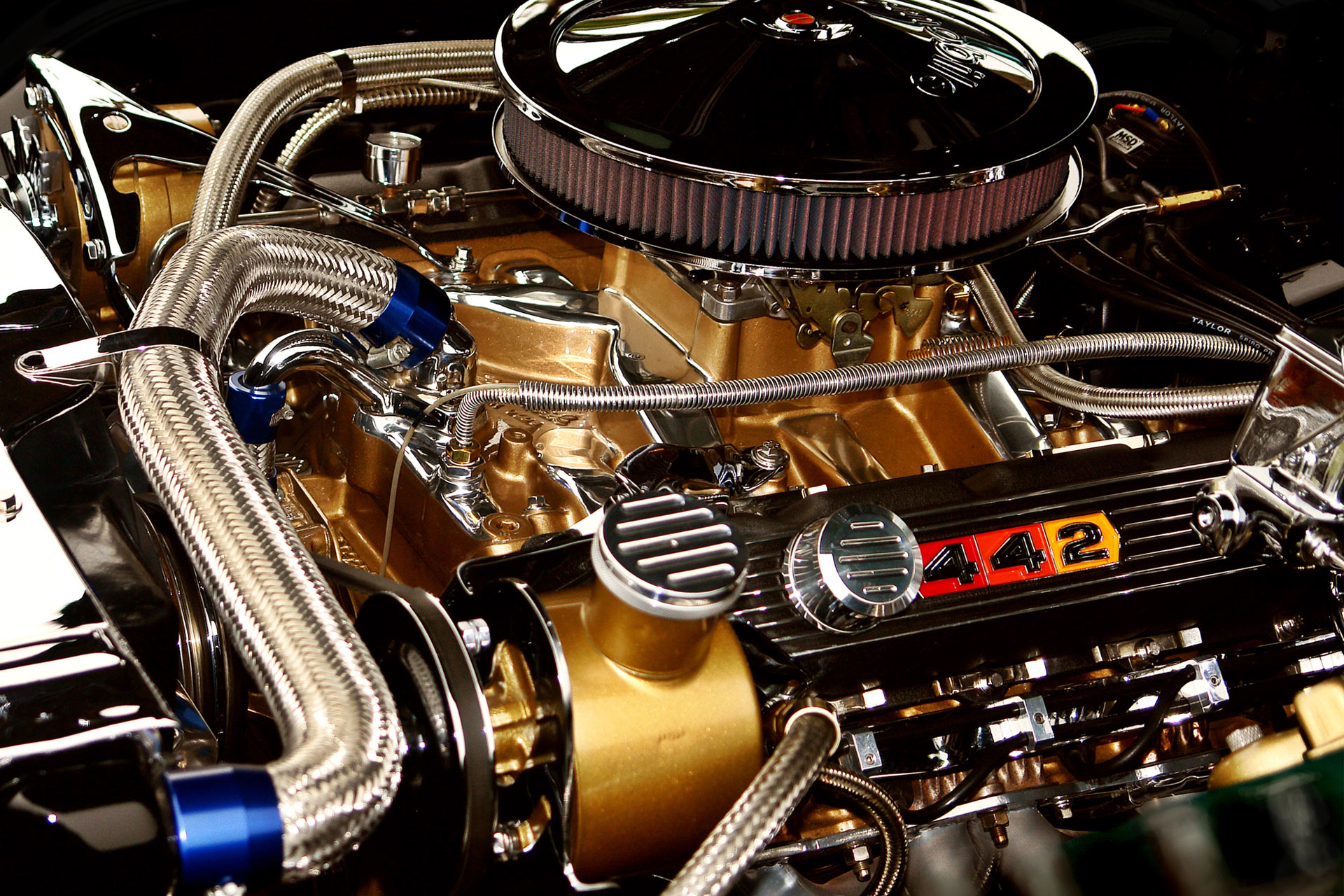

Block and Cylinder Resurfacing

Today’s engines have very demanding sealing requirements, including the finish that is required on the cylinder head and engine block deck surfaces to seal the head gasket. High quality surface finishes are required because of changes in gasket designs, engine designs and engine loads.

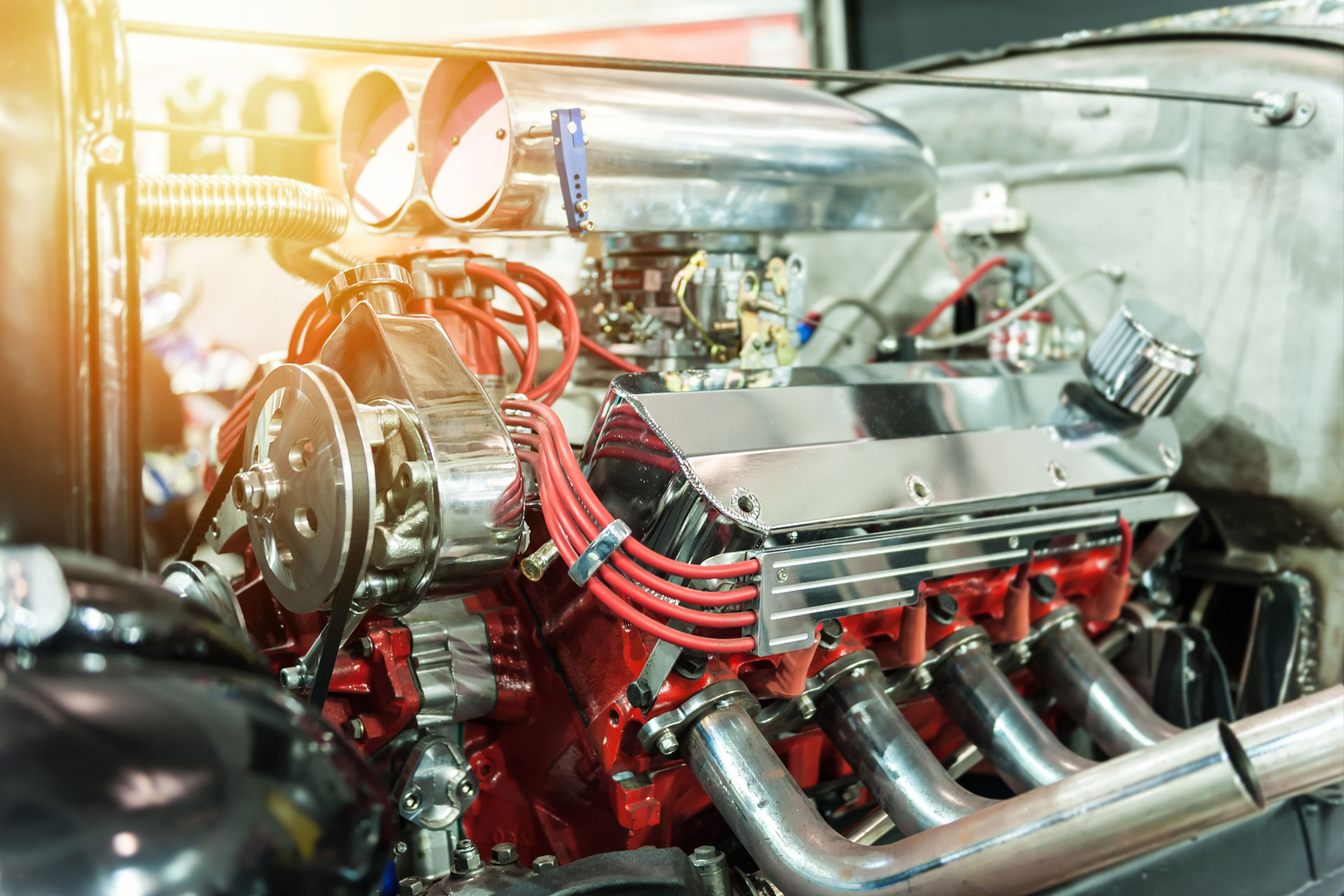

Cylinder and Rod Honing

When an engine is rebuilt, the cylinders usually need attention. Wear tends to create taper in the upper part of the cylinder that can reduce ring sealing and increase blow by and oil consumption if not removed. The cylinder may also be out of round, scored or have other damage that requires correcting before a new set of rings will seal properly.

The main objective when refinishing the cylinders is to make the walls as straight as possible (no taper), the bores as round as possible (minimal distortion, which is especially important with low tension rings), to have the right amount of crosshatch for good oil retention and ring support, and to produce a surface finish that meets the requirements of the rings.

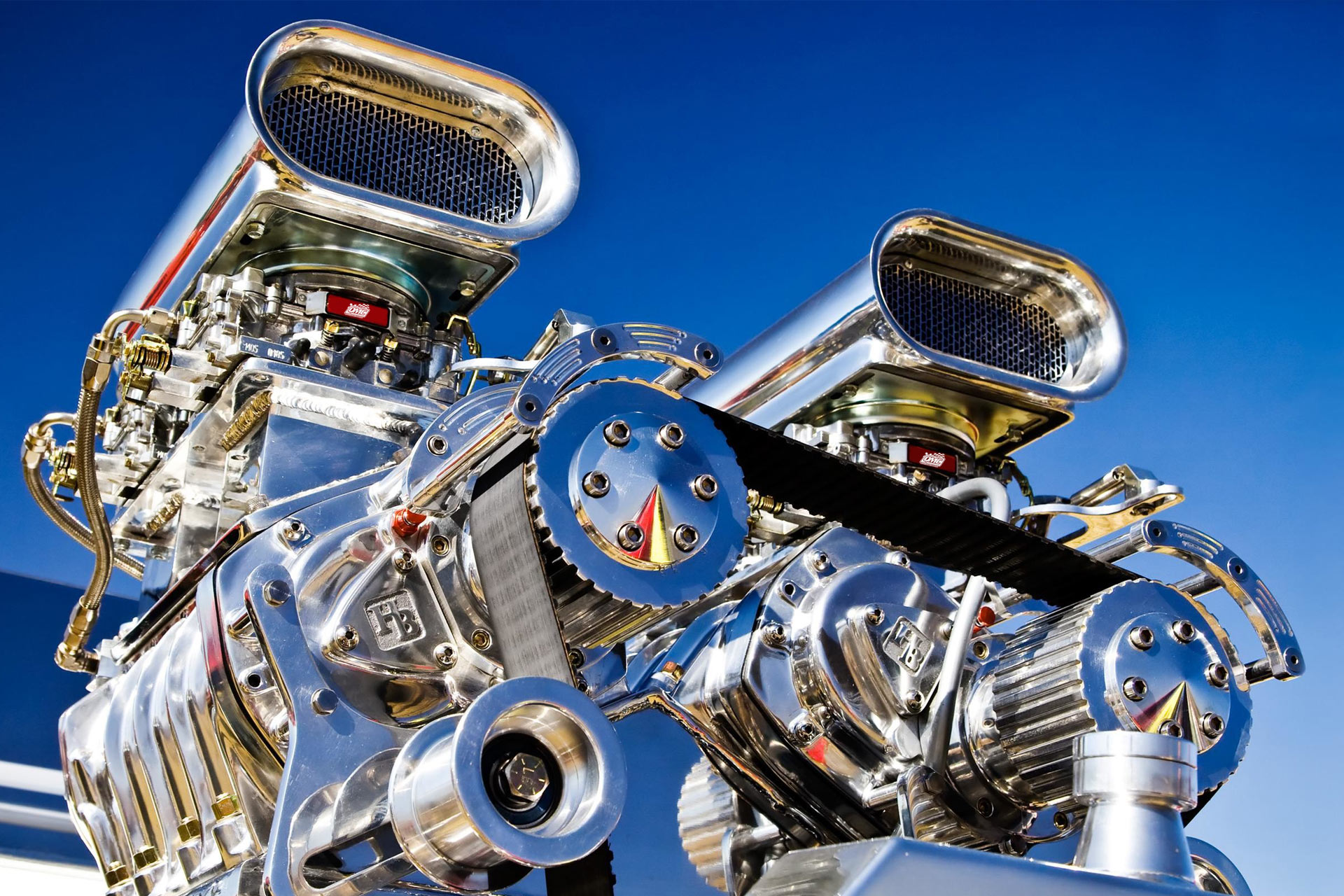

Engine Balancing

Your engine will run smoother and last longer if balanced correctly, and the cost of balancing your engine will pale in comparison to the potential future costs of an unbalanced engine. An unbalanced engine can shorten the life of/or destroy critical engine parts as well as being annoying and distracting.

Dyno Testing

For an engine builder going to the dyno for the first time the process can be intimidating and confusing. At Quality Machine, we make the dyno process easy for you, making the rewards well worth the time and money. Dyno time is so important to your engine project that it should be regarded with the same enthusiasm and attention to detail as the engine build itself.

Contact us

"*" indicates required fields